Realtrac ERP Software Material Planning

Every shop owner in the manufacturing industry has faced the scenario of non-conformance material. Fortunately, Realtrac’s MRP function provides quick and easy answers to the what, where, when and how.

Thursday, 3 PM.

Your best customer calls and says: “The

part you just delivered? I had one shear in half. I think there’s a problem

with the steel used in the part.”

|

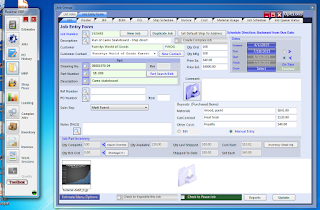

| Figure 1 - The Job that made the faulty part |

You now have some questions to answer: What jobs on the floor

use the same stock? Which customers have you already delivered parts to, using

the same material? And, how long will it take you to collect that data? Fortunately,

you can answer all these questions in under 2 minutes with the Realtrac

MRP feature!

So, how can you tell what jobs and parts used the same lot

of steel? Let’s walk through the three steps required to discover this critical

piece of business information.

Step #1: Navigate to the original job with the material being returned.

|

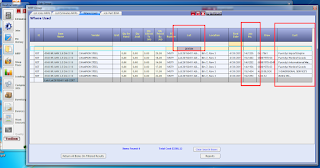

| Figure 2 - Lot information on the Material Usage tab |

Step #2: Click on the “Material Usage” tab at the top of the screen.

On my return, this shows me

all the materials consumed in the production of the material. I used 18 pieces

of 4140 that may be faulty, and I see the lot number that the material came in

on.

Step #3: Click the “MRP” button, and type the beginning entries of the lot number.

The Realtrac ERP Software search will instantly

display the jobs and customers who are potentially affected by the non-conforming

steel material.

|

| Figure 3 - Searching the MRP feature for the Lot of steel |

In just three clicks, I have a full report on

all the parts, jobs and customers who might be impacted. I can reach out to

those customers, see the status of each job and if they’re still on my floor,

or I can continue to study the issue. What’s important is that I don’t need to

go to an outside source, and I don’t need to contact my vendors or customers. I

have my purchasing, inventory and true product and material tracking in one location. No more stress and anxiety

for manufacturing shops using Realtrac!

Call us today at 734.793.3811,

or email questions and comments to sales@realtrac.com!

About REALTRAC

Based in Livonia, Michigan, REALTRAC Performance ERP is a manufacturing ERP software company specializing in ERP software for machine shops,

job shops and make-to- order metal working manufacturers. The company

was founded in the heart of a machine shop and has served the

manufacturing industry for over three decades. The program is used by

thousands of users across North America. REALTRAC 10 was released in

March 2014.

No comments:

Post a Comment