Realtrac’s World Headquarters are based in Livonia, Michigan,

and are part of the “MMS 2014 Top Shop”-awarded, Delta Research Corp. But the

development team needs to know what software and features the marketplace

needs… and this guidance comes from the Realtrac Steering Committee.

The Realtrac Steering Committee is made up of Customer

Machinists, Customer Management teams, members of the ownership, and Realtrac sales

and marketing teams. All of these committee members are influential in the

process of deciding which features and functions should be included in the

system. The Realtrac sales and marketing team is the driving force of the

committee, as they are on the front line of customer requests and inquiries.

While Realtrac’s parent company, Delta Research, Corp.,

heads the steering committee, Realtrac enjoys a hands-on approach to acquiring

information for best machine shop practices. One example: in preparing for the

2014 tax season, the Realtrac Steering Committee, along with one prime customer

of Delta Research, decided to invest development resources to make it easier

for Realtrac users to claim their fair share of the United States Federal

Research and Development tax credit. The sales and marketing team confirmed

they had requests from their customers for this feature. We knew that what was

good for one user could benefit many Realtrac users.

In general, a development team will break a New Feature

request like this into two broad categories: Input (what information we should

allow the user to enter into the Realtrac Performance ERP system), and Output (what

reports and forms the system needs to generate to achieve the desired result).

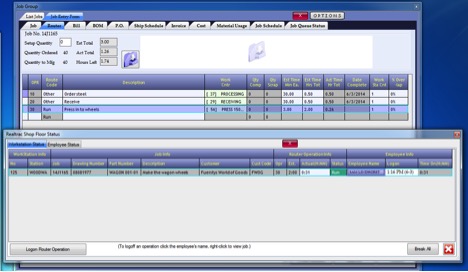

Input-wise, we already had mechanisms in place to capture

costs. Shop floor employees log in and out of jobs on a daily basis, so we

already knew exact labor costs, as well as when they happened. Within our

database we know down to the penny how much was spent on labor over the course

of a company’s fiscal year. Not all jobs run through a shop are eligible for

the tax credit, but the Realtrac job tagging mechanism already provided the

perfect way to flag a job. While the development team went to work, we simply

asked the Realtrac user to begin adding the tag "RD14" to jobs they

believed were eligible for the credit.

Output-wise, we determined that two new reports were

necessary. We developed a report that broke down every employee’s labor hours

and costs for R & D jobs over the course of the company’s fiscal year. The

second report examined the buyout/material expenses related to the R & D

jobs. These two reports—produced with a click of a button in the Realtrac

Performance ERP software, along with a simple “org” chart and a breakdown of

administrative costs—were all that the Realtrac users’ accountants needed to

prepare the claim.

Every step of the way, the Realtrac development team was

working hand-in-hand with the Realtrac Steering Committee, Delta Research, and

a third-party tax and accounting consultant the Steering Committee brought in

to help guide the development process.

The best moment of the whole process? One very satisfied

Realtrac customer who filed their claim for hundreds

of thousands in credits. Their 2014 tax return is complete, and their

Realtrac system has already been capturing costs for their 2015 return. Completing

the claim next year is going to require no extra work. They’ll just need to tag

eligible jobs and run the report at the end of the year!

Admittedly, the second best moment of the process was when the

tax consultant said the Realtrac Performance R&D reports were the most

complete, simplest presentation of the required documentation and information

they have received from any software product, ever.

To all of our

existing customers — please continue talking with Realtrac and your sales

reps about what's going on in your business. What challenges can we help you with?

What information do you need to help drive your business, improve sales, or cut

costs?

Keep an eye on our social media and website—the R&D

Feature is being officially released in our September, 2015 update; plus, we

will be releasing a training video showing how the feature works, and helping

get our users ready to file their 2015 claims.

To all of our future

customers — keep this narrative in mind when deciding on your future ERP

system. These formal conversations

between the Realtrac Development team and the Steering Committee occur weekly

and even daily, informally.

Realtrac is unique in that it’s guided on a daily basis by a

machine shop. So, features that benefit the Delta Research shop are very likely

to benefit your machine shop.

Give Realtrac a call. We can set you up with a complete

machine shop ERP system, including a great new feature that will automate the

process of applying for your Federal Research and Development tax credit—all in

under a week!